Harness the power of Big Data and Connected Vehicles

To improve quality, safety, and resilience of your road network.

One out of every five miles of highway pavement is in poor condition. The backlog of existing highway maintenance is estimated to be $420 billion or 50% of the US highway and bridge capital needs.

One out of every five miles of highway pavement is in poor condition. The backlog of existing highway maintenance is estimated to be $420 billion or 50% of the US highway and bridge capital needs.

Current repairs for road infrastructure are often based on costly, time-consuming, and human-intensive surveys.

The manual process of conducting these surveys is often lengthy and difficult which result in frequent delays and additional cost.

The manual process of conducting these surveys is often lengthy and difficult which result in frequent delays and additional cost.

Due to various constraints, road management agencies are unable to fully inspect their road networks with meaningful frequency.

Lengthy inspection and reporting turnaround means a lack of true current assessment of road infrastructure, and reliance on secondhand or outdated information.

i-Probe offers a

TECHNOLOGICAL SOLUTION

to these challenges

Connected Vehicles are at the core of i-Probe technology. Through our strategic development partnership with Honda Motors, we have developed our entire system to leverage the existing sensors in regular late-model production vehicles.

Connected Vehicles are at the core of i-Probe technology. Through our strategic development partnership with Honda Motors, we have developed our entire system to leverage the existing sensors in regular late-model production vehicles.

No aftermarket installation of additional equipment is necessary.

With only the pre-installed onboard sensors, i-Probe is able to capture pavement conditions and translate the data into pavement distress mapping and insights. Learn more about our data collection methods below.

Work Process

1

Data Collection

2 Methods:

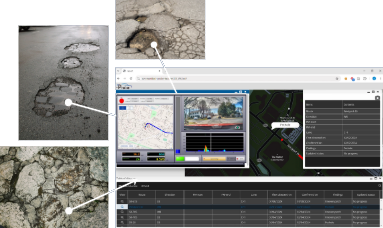

RoCoMo BDAS

Continuous data collection through fleet crowdsourcing.

SRMCV

Near real-time monitoring with a custom Connected Vehicle.

2

Analysis

Automated pavement distress identification and classification with video verification.

3

Mapping

Delivers custom pavement condition mapping with superior turnaround time.